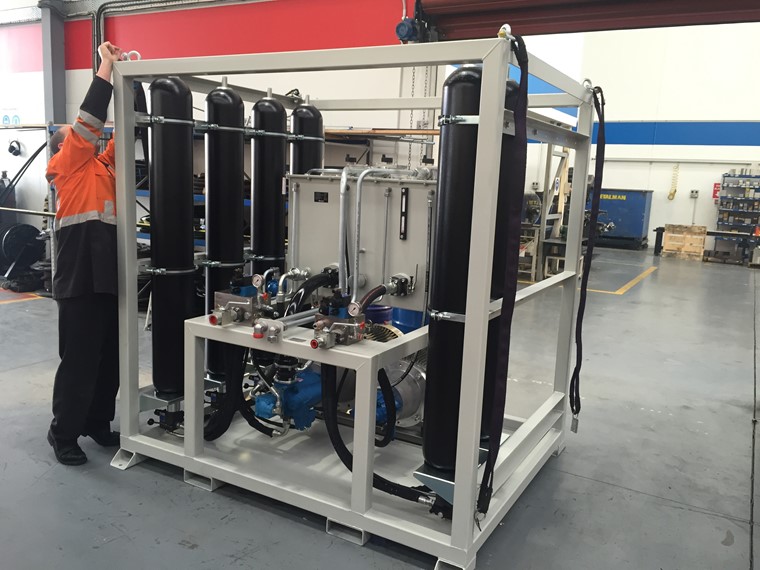

These lines operate at a very high duty cycle often for 24 hours a day. To survive these high cyclic conditions the hydraulic components must be robust and of the highest quality. During the design phase we ensure that the best products for the application are selected.

The hydraulic powerunits are designed so that all parts are easily serviceable. Sensors ensure that oil temperature and quality are maintained within optimum operating limits.

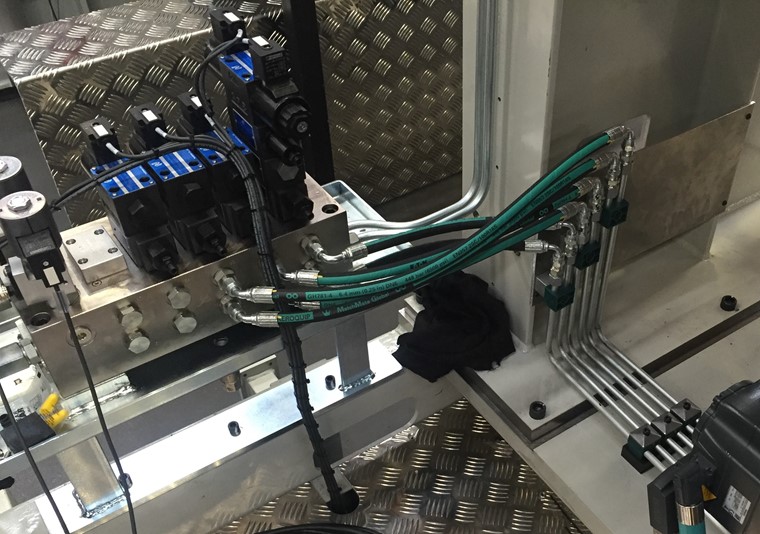

All the hydraulic manifolds on the line are designed and manufactured by Hytech (Hyspecs Technologies) and made from cast steel that’s been nickel plated.

We use resources from Auckland and our other branches to help complete the installation and commissioning on time. Installation can typically be 6 to 8 weeks per production line and we use hundreds of metres of hydraulic hose and tube.